Microphone for Integration with a Xiris Weld Camera

WeldMic™ allows welding operators to clearly hear, record and playback welding sound.

Unlike most commercial microphones, WeldMic™ is built to survive in harsh welding environments. Featuring a rugged body, robust cables and specialized internal electronics, WeldMic™ gives fabricators another sensory input – sound – to help them remotely monitor and fine-tune the welding process.

Using Xiris weld camera software, users can set up, record and EQ audio and synchronize it with welding images. Multiple welding stations can be monitored simultaneously, as the audio signal is plotted in a rolling window making it less reliant on real-time observation.

Designed for Easy Integration

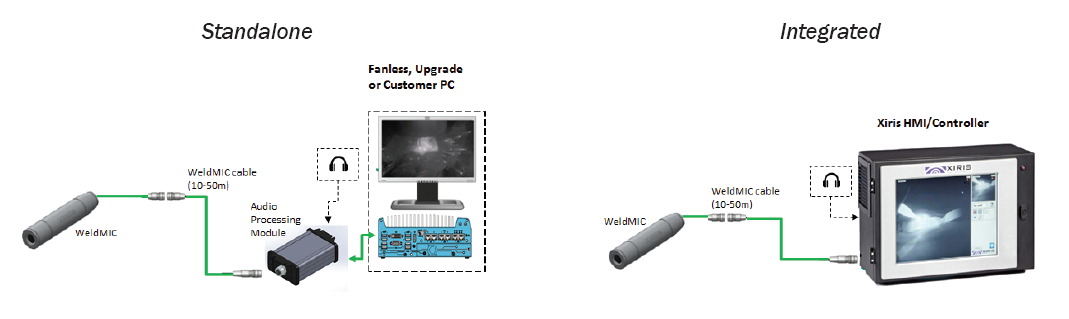

For existing Xiris weld camera systems or where a Xiris weld camera is connected to a 3rd party PC, the stand-alone WeldMic™ kit with a separate Xiris Audio processing module can be easily added and connected via a short USB cable. The Integrated option is for new Xiris camera systems using the Xiris HMI/Controller minimizes additional cables and footprint.

A single industrial audio cable connects the WeldMic™ to the Xiris audio card installed in the Xiris HMI (integrated with the Xiris camera system), minimizing the need for additional cables or interfaces. Includes a standard 3.5mm audio jack on the front panel of the HMI for audio out to connect to earphones or an external speaker, for listening live or reviewing playback sounds.

Specifications

Accessories

Software

Documents

Service & Support

Specifications

System Specifications

Dimensions: 18(D) x 80(L) mm (0.7 x 3.2″)

Weight (Approx.): 95g

Frequency Response: 50Hz – 20kHz

Temperature Operating: 0° – 70° C

Dynamic Range: + 120 dB Sound Pressure Level

Humidity Operating: 20 – 90% (non condensing)

Power Consumption: Maximum 2 W via Xiris Audio Interface

Audio Out: 3.5mm TRS Audio Jack (for Earphones or External Speaker)

Compliance: CE, FCC-B, RoHS

Accessories

Microphone Mounting Clamp / Flex arm (optional)

Microphone Cable and Connectors 10, 20, 30, 40, 50m cables with M12 connectors

Software

WeldMic™ is fully compatible with the latest Xiris WeldStudio™ or XVC-1000e System software that includes the audio processing module, a 10 band Equalizer (EQ), microphone controls and visual audio waveform displays.

Audio Controls 10 band frequency EQ, Gain & Volume control, Mute, Recording, and Playback

Data Audio is encoded with video and recorded as an .AVI fi le (48kHz – 16 bit)

Software Upgrades

Xiris releases a major new release of software on average once a year. Minor upgrades occur more frequently. Our technicians may upgrade client systems while on site at a client’s request.

Service & Support

Contact Support – Monday – Friday: 0830 – 1730 Eastern Standard Time

Phone: +1.905.331.6660

Fax: +1.905.331.6661

Email: support@xiris.com

Our partners also provides support and service to our clients at many locations around the world.

Service & Training

Xiris provides its customer base with various levels of service, including new system installation and training, system upgrades and preventative maintenance programs. Many of our partners are trained to offer additional support on our systems.

System Upgrades

Many of our older systems in the field have been upgraded to allow the use of new hardware and software features including improved system reliability, system security, production reporting and updated operating systems. Do you have an older Xiris vision system? Please call your Xiris account manager to receive more information regarding the immediate benefits of a system upgrade.

Preventative Maintenance Visits

Many of our clients request a Preventative Maintenance visit in conjunction with a new system delivery or as a separate service. Our technicians will optimize the performance of the system, upgrade software as applicable, look for potential part failures and conduct training as desired by the client during the visit.

Warranty

All Xiris systems are shipped with a 15-month warranty from the day of shipment from Xiris or a 12-month warranty which commences from the first day of use (whichever comes first). Please have your Xiris system serial number available when you call so we can determine your system warranty status as well as your support plan level.

Once your Warranty expires, your Xiris Account Manager will contact you to discuss your long term support needs. Xiris offers different levels of support plan.

Let us show you the difference WeldMic™ makes.

Join us for a video demo and info session