The Xiris HF Pre-Weld Inspection system enables operators to remotely monitor strip edges and the welding process of High-Frequency Tube Mills.

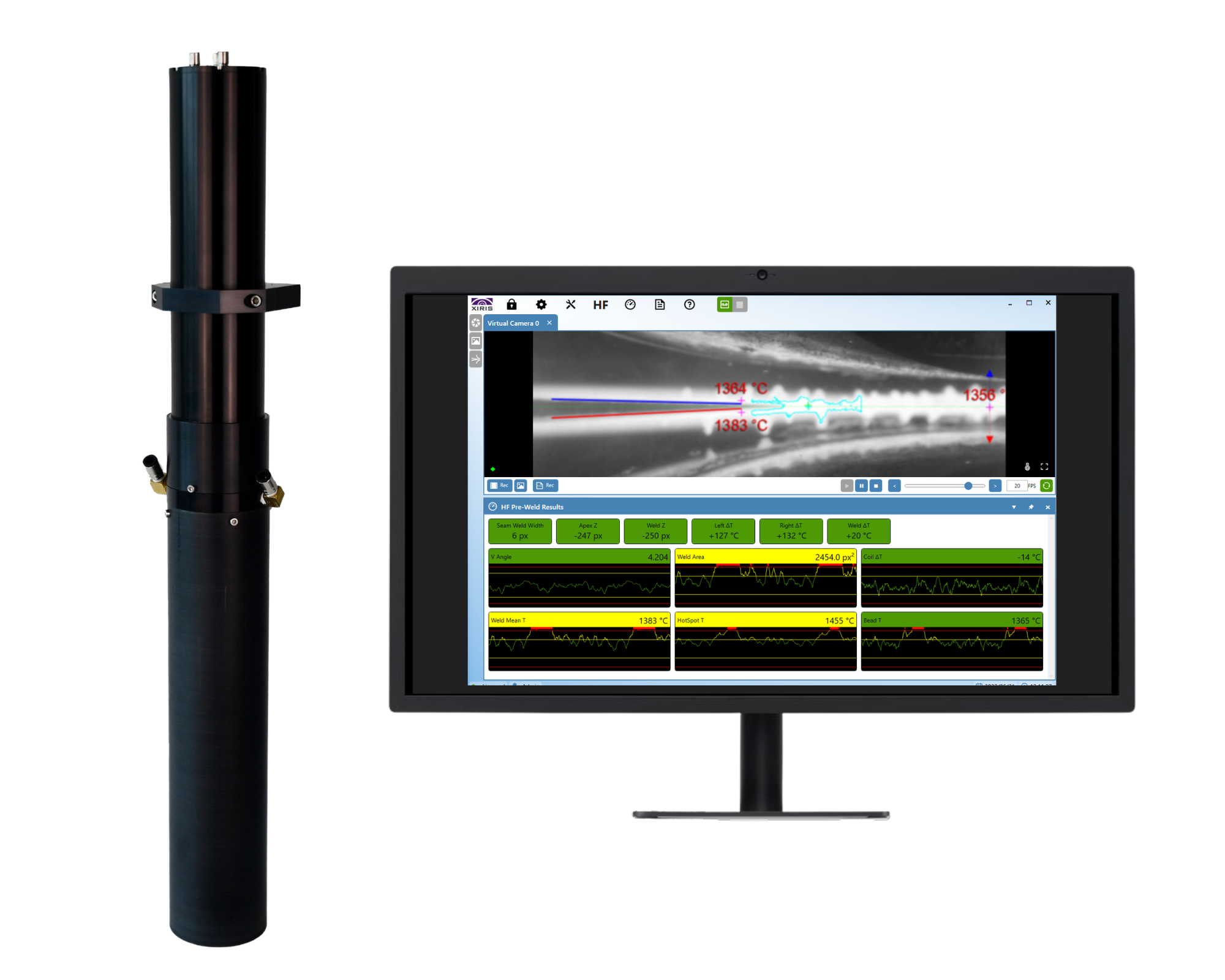

This solution, featuring the XIR-1800 thermal camera in a robust protective housing and an intuitive HMI computer, empowers you to achieve remarkable results on High-Frequency Tube Mills.

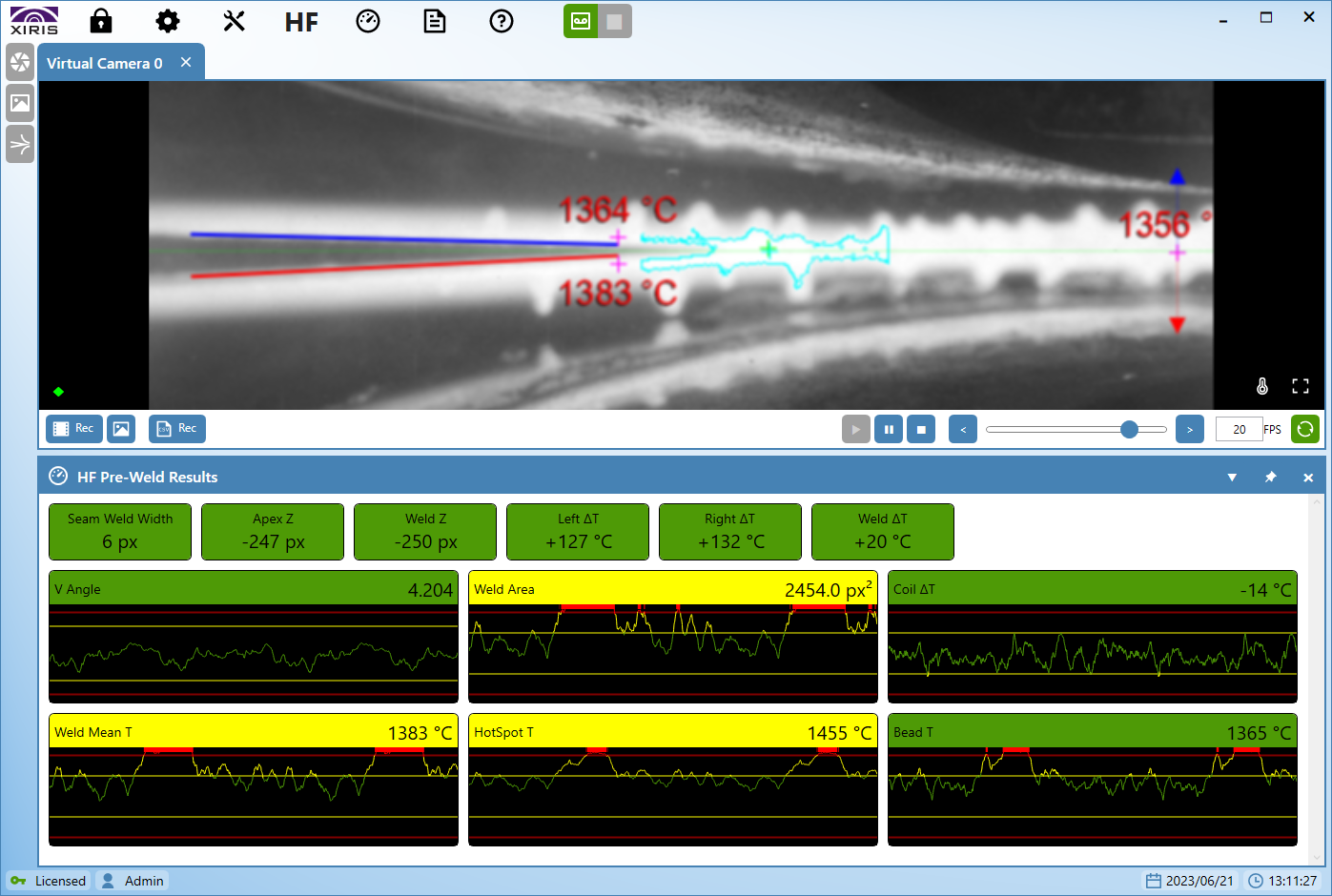

The HF Pre-weld system enables operators to remotely monitor strip edges and welding temperatures with ease.

Using advanced software, the system can measure, monitor, and record multiple process parameters, putting you in full control of your welding operations.

With real-time data and numerous measurements calculated (+30 times/second), you will enhance tube welding quality and optimizing production efficiency effortlessly.

The HF Pre-Weld Inspection system’s cutting-edge technology analyzes both geometric and thermal data, delivering valuable insights to ensure a stable welding process, prioritizing product quality and uncompromised safety.

Elevate your welding experience with the HF Pre-Weld Inspection system – a transformative solution that sets new industry standards and opens the door to unparalleled welding excellence.

Simplified Workflow

Operators get a real-time view and data tracking with limit alarms. Data can be communicated and stored for troubleshooting and sorting if needed.

Streamline operations with permission and recipe management. Save, recall, and make product changes to optimize efficiency and enhance productivity.

Let us show you an unprecedented view of the welding process

Join us for a video demo and info session